Looking to swap out a failing engine but keep your lawnmower chassis? I was wondering the same thing. Is it true, are lawn mower engines interchangeable?

The answer is yes, push lawn mower engines have standard mounting points and can be installed on any gas push mower chassis. The drive shaft and self-propelling accessory drives don’t always align and must be checked.

Yes, riding lawn mower engines have the same bolt pattern and are interchangeable. What may vary includes how the throttle cable is connected, the wiring harness, the pulley system that moves the mower and spins the blades, the fuel line, and in-line filter location, and how the starter connects to the engine.

No electric mower engines vary dramatically and are not interchangeable.

But how much work is required to do this? What’s the cost of a new engine? How much skill do you need?

Keep reading for these answers and more.

Note: If you click some of the links in this article we may earn a small commission at no additional cost to you.

When Should You Change Out Your Engine?

Typical lawn mower engines should last 1,500 hours. If it takes you an hour to mow your lawn and your mowing once a week for 6 months then your lawnmower should last for 62 years at that rate or pretty much as long as you’ll be in the house.

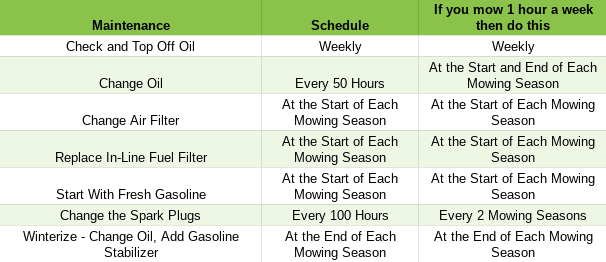

This assumes you change the oil and air filter as required. Follow this maintenance schedule and you should never need to change out your engine:

| MaintenanceScheduleIf you mow 1 hour a week then do thisCheck and Top Off OilWeeklyWeeklyChange OilEvery 50 HoursAt the Start and End of Each Mowing SeasonChange Air FilterAt the Start of Each Mowing SeasonAt the Start of Each Mowing SeasonReplace In-Line Fuel FilterAt the Start of Each Mowing SeasonAt the Start of Each Mowing SeasonStart With Fresh GasolineAt the Start of Each Mowing SeasonAt the Start of Each Mowing SeasonChange the Spark PlugsEvery 100 HoursEvery 2 Mowing SeasonsWinterize – Change Oil, Add Gasoline StabilizerAt the End of Each Mowing SeasonAt the End of Each Mowing Season |

Cost To Change A Lawn Mower Engine – Is It Worth It?

Is it even worth it to install a new engine? A brand new lawnmower with everything including will run you $100 for a basic low-end model up to $300 for a high-end self-propelled mower. The average runs somewhere between $160 and $220.

A new lawnmower engine from Harbor Freight is currently going for about $99. Assuming it will take you at least 1/2 a day to go over there, buy the engine, take off the old one, and install the new one, is it really worth it?

Yes, there are YouTube videos of mechanics (experienced in this) changing out a mower engine in 15 minutes. But they already had the engine there. They already had all the tools. They’ve done it enough times that they know the ins and outs of making the throttle cable work and hooking up the drive train both to the blade and to the self-propelling system.

Most newbies figuring this out will take several hours if you include the initial trip to buy the engine plus the extra trips to get special bolts, parts, and tools that may be required for your specific engine.

So is it worth it to swamp the motor?

Yes if you have a used motor lying around and you don’t mind spending a few hours swapping them out.

No, if you need to buy a new motor. It’s easier and only slightly more expensive to buy a whole new lawnmower and give your old one to a local mechanic.

Engine Specs to Look Out For – Will My New Engine Match The Crankshaft?

When changing out an engine be sure to check the following items to make sure the new one will fit and power everything as needed:

- Do the bolts of the new engine match the size and threading of the old engine?

- Do you have other nuts if needed to match the new bolts?

- Does your lawn mower have a self-propelled drive train? Will the new engine accomodate this?

- Can you easily disconnect the throttle cable and will it stretch far enough to connect to the new engine?

- Will your lawn mower blade fit the new crank shaft? Center holes and shear pin holes come in different sizes. If not do you have a blade that fits the new engine? See our article on lawn mower blades prices and sizing here.

Are Riding Lawn Mower Engines Interchangeable?

Yes, riding lawn mower engines have the same bolt pattern and are interchangeable. What may vary includes:

- How the throttle cable is connect

- The wiring harness

- The pulley system that moves the mower and spins the blades

- The fuel line and in-line filter location

- How the starter connects to the engine

Before you change out a riding lawn mower engine ask yourself, can I save the old engine?

- Does it need a new battery?

- Does it need a new starter?

- Does it need a new alternator? The above three could be with a battery/alternator testing kit

- Is it leaking oil or gas? This is where we start to get into reasons to change the engine

- Is the oil pan leaking? Can it be replaced?

- Is it leaking from the head gasket? Can it be easily replaced? If the engine warped due to an overheating and damaged head gasket then you might want to consider a new engine.

- Is it leaking from the carburetor? Can you replace that assembly?

- Is the fuel pump leaking? Can you replace that?

Are Electric Lawn Mower Engines Interchangeable?

No electric mower engines vary dramatically and are not interchangeable.

While there’s an underground movement of converting your old gas mower to an electric one, expect to drill new mounting holes in your current chassis.

If you buy a new electric engine that exactly matches your old one you’ll be OK. Otherwise check the specs and mounting bolt spacing on any potential new engine to make sure it matches the old.

Steps To Change a Gas-Powered Push Lawn Mower Engine

Swapping out the engine on a push lawn mower (gas-powered) is pretty easy. Expect it to take about half a day. Yes, you can do it in “15 minutes” like in the video below.

But that doesn’t include the time to drive out and get the engine, learn how to do all the steps below when you’ve never done them, and go out for extra trips for more parts or tools.

Even in the demo video, they end up pausing it to find nuts that fit the new mounting bolts as they used a non-standard thread.

Expect that to happen and more.

Follow the steps below and watch the video for a demo:

- Remove the blade

- Disconnect the mounting bolts

- Disconnect the throttle cable.

- Pull off the old engine.

- Add the new engine

- Tighten the nuts onto the new mounting bolts. Check that you’ve got the right threading. See mixup in the video below.

- Attach the blade. Make sure it rests in a similar position as the previous one (not too high or low). You may need to add spacers to the mounting bolts to raise it up.

- Attach the throttle.

- Start and test the mower.

19 Easy Steps To Change a Riding Lawn Mower Engine

Riding lawn mowers have a few extra steps. Expect this to take a full day if you’re new to it. Yes, in the video below again they do it in an hour. That’s because they do it a lot!

- Get the new engine

- Put on the parking brake. Sometimes this will loosen the belts pulling on the drive train. Sometimes not.

- Jack up the front of the mower. This ensures all the gas drains back down to the tank. Have a spill kit ready just in case.

- Disconnect the gas line going into the carburetor. Drain any excess gas into a clean container.

- Disconnect the throttle line.

- Disconnect the starter. Don’t pull it out. Just disconnect the wires going to it. Only key start systems will have this. Pull start engines won’t.

- Unscrew the engine mountain bolts.

- Loosen the engine and pull the belts off the crankshaft pulleys.

- Remove the engine.

- Remove the crankshaft.

- Attach the crankshaft to the new engine.

- Install the new engine onto the mounts. Keep it loose, don’t tighten anything.

- Reattach the belts to the crankshaft pulleys.

- Tighten the mounting bolts.

- Connect the starter.

- Connect the throttle line.

- Connect the gas line.

- Fill the gas and oil tanks as needed.

- Start and test the new engine.

Steps To Change An Electric Lawn Mower Engine

Changing out an electric lawn mower can be a chore. Before doing that see if you can troubleshoot it. Sometimes just changing out the motor brushes will do the trick.